Exploring Metal Castings and their wide-ranging uses across multiple industries

Recognizing the Steel Castings Process: A Comprehensive Overview for Beginners

The Metal Casting procedure is a basic method in producing that transforms molten steel right into solid types. Newbies should comprehend the different methods involved, such as sand casting and die casting. Understanding the products, layout concepts, and precaution is equally important. Each facet plays an important duty in attaining effective results. As one browses these intricacies, the concern of how to optimize each action for improved outcomes ends up being increasingly pertinent.

The Essentials of Steel Casting

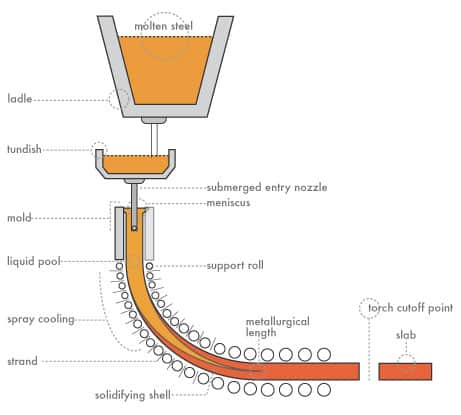

Metal Casting has actually evolved over centuries, its fundamental principles stay important and constant to the production procedure. At its core, Metal Casting includes the transformation of molten steel right into solid things with various techniques. The process begins with the creation of a mold and mildew, which specifies the shape of the last item. Once the mold and mildew is prepared, metal is heated up to its melting factor and poured right into the tooth cavity. After cooling down, the metal solidifies, taking the form of the mold.

There are numerous casting methods, including sand casting, investment spreading, and pass away spreading, each with unique advantages and applications. The selection of technique depends on factors such as production volume, product type, and wanted accuracy. Once cast, the final product may go through added procedures like machining or surface treatment to accomplish the needed finish and specs. Comprehending these essentials is important for any person curious about the area of Metal Casting.

Understanding Materials Used in Steel Casting

Materials play a vital function in the Metal Casting procedure, influencing the end product's properties and efficiency. Different metals are made use of, including light weight aluminum, steel, bronze, and iron, each offering distinct features matched for particular applications. Aluminum is light-weight and corrosion-resistant, making it perfect for auto parts. Iron, especially cast iron, is preferred for its outstanding wear resistance and toughness. Steel offers high stamina and convenience, typically utilized in hefty machinery components. Bronze, known for its corrosion resistance and machinability, is typically utilized in aquatic applications.

Along with the steels, various casting materials, such as sand, plaster, and ceramic, are used to produce molds. Sand spreading, one of the most prevalent technique, makes use of silica sand due to its thermal security and capability to develop complex forms. Plaster and ceramic molds provide finer details but might require more intricate processes. The option of materials straight influences the effectiveness, expense, and high quality of the spreading procedure.

The Design Refine: From Concept to Plan

The layout process in Metal Casting starts with the first idea development, where ideas are produced and reviewed. This is complied with by the application of CAD modeling strategies, enabling specific visualizations of the style. The blueprint finalization actions assure that all specifications are properly documented for production.

Preliminary Principle Growth

Preliminary idea advancement notes an essential stage in the Metal Casting process, where concepts transform into tangible styles. Throughout this stage, developers team up with designers and stakeholders to brainstorm and fine-tune first ideas. They think about aspects such as performance, visual appeals, and manufacturability, making certain that the design fulfills the needed specs and efficiency criteria. Sketches and rough drafts are produced to imagine the principles, permitting preliminary evaluations of feasibility and cost-effectiveness. This stage likewise includes determining materials and potential casting approaches that straighten with the design goals. Eventually, preliminary principle advancement lays the foundation for an extensive plan, assisting the subsequent phases of the spreading procedure and ensuring an effective change from idea to fact.

CAD Modeling Techniques

Transforming concepts into specific layouts, CAD modeling strategies play a pivotal function in the Metal Casting procedure. These strategies utilize innovative software program to create detailed three-dimensional models that accurately mirror the desired item. By utilizing tools such as parametric modeling, solid modeling, and surface modeling, designers can manipulate dimensions and forms with convenience. CAD systems also promote simulation and evaluation, enabling the identification of possible flaws prior to manufacturing starts. This proactive strategy minimizes material waste and optimizes the layout for manufacturability. Additionally, CAD versions can be conveniently changed, enabling fast versions based upon feedback. Essentially, CAD modeling works as the foundation of the design procedure, connecting the space in between first ideas and the ultimate production-ready designs.

Blueprint Completion Tips

Complying with the production of thorough CAD designs, the next stage includes plan finalization, which is critical in converting electronic layouts right into workable strategies for production. This procedure starts with examining the CAD designs for precision and conformity with specifications. Once validated, the measurements, tolerances, and product specs are meticulously outlined to ensure quality. Incorporating notes and notes helps interact important info regarding spreading processes, surface area coatings, and setting up needs. The wrapped up plan goes through a strenuous authorization process, commonly entailing cooperation with designers and production groups to attend to any potential issues. Nevertheless modifications are made and authorizations obtained, the plan is officially launched, acting as the foundational file for the subsequent phases of Metal Casting, including pattern making and mold design.

The Steel Casting Methods Explained

Metal Casting visit the website strategies include a range of methods made use of to form molten metal right into wanted forms. These methods vary according to the kind of material, intricacy of the design, and production quantity. Sand casting is just one of the most common approaches, including the production of a mold and mildew from sand to hold the molten metal. Investment casting, or lost-wax casting, allows for detailed designs by utilizing a wax pattern that is dissolved. Die casting employs high-pressure shot of liquified metal right into a mold and mildew, ideal for automation. Other techniques consist of long-term mold and mildew casting, which makes use of recyclable mold and mildews, and centrifugal spreading, where rotational forces assist in loading the mold. Each method has its applications and advantages, making it vital for manufacturers to choose the ideal approach based upon their details needs and needs. Understanding these strategies is necessary for any individual associated with the Metal Casting procedure.

Ending Up Procedures: Enhancing Your Casted Product

Finishing procedures play a crucial function in enhancing the top quality and look of casted products. Numerous surface area treatment methods, such as polishing and finishing, are utilized to improve toughness and appearances. In addition, top quality assessment approaches assure that the last item satisfies defined requirements and efficiency needs.

Surface Area Treatment Methods

A range of surface area treatment strategies play a vital function in improving the top quality and long life of casted items. These strategies include methods such as shot blasting, brightening, and finishing. Shot blasting successfully removes surface imperfections, enhancing the aesthetic and practical qualities of the spreading. Polishing supplies a smooth surface, which is especially essential for decorative applications and elements requiring very little friction. Finishing methods, such as electroplating or powder coating, deal extra defense versus corrosion and wear, ensuring longevity. Surface area therapies can improve bond for succeeding processes, such as paint or bonding. By using these techniques, suppliers can accomplish exceptional surface area high look at this now quality, which is vital for the performance and lifespan of Metal Casting in numerous applications.

High Quality Assessment Approaches

Efficient high quality inspection approaches are necessary for ensuring the stability and performance of casted products after the ending up processes. Different techniques are used to examine the quality of Metal Casting, including aesthetic inspection, dimensional checks, and non-destructive testing (NDT) Visual inspection permits the recognition of surface area issues, while dimensional checks assure that items satisfy specified tolerances. NDT techniques, such as ultrasonic testing and radiographic examination, offer much deeper insights right into inner honesty without harming the spreadings. In addition, mechanical testing, such as tensile and solidity examinations, reviews material properties - Metal Castings. By utilizing a mix of these approaches, producers can enhance item high quality and reliability, inevitably resulting in higher client satisfaction and decreased manufacturing prices

Safety And Security Considerations in Metal Casting

While the Metal Casting process supplies countless advantages, it also provides a variety of safety and security threats that should be thoroughly taken care of. Employees in casting facilities are exposed to heats, molten metals, and dangerous materials, which can lead to severe injuries if correct precautions are not taken. Individual safety equipment (PPE) such as heat-resistant handwear covers, deal with guards, and safety clothing is important to decrease threats.

Additionally, the existence of fumes and dust requires appropriate air flow systems to ensure air quality - Aluminum Castings. Routine training on security protocols is essential for all employees to identify prospective hazards and react effectively. Emergency situation site web procedures must be established, including fire precaution and emergency treatment schedule. Maintenance of equipment and appropriate handling of products further add to a safer working atmosphere. By focusing on these safety and security considerations, Metal Casting operations can safeguard their labor force and keep efficient manufacturing procedures

Frequently Asked Inquiries

What Are the Ecological Impacts of Metal Casting?

Metal Casting can result in environmental impacts such as air and water air pollution, source exhaustion, and power intake. Additionally, inappropriate waste monitoring and discharges from foundries add to eco-friendly disruptions and wellness risks for close-by communities.

Just how Do I Select the Right Metal for Spreading?

To select the best steel for casting, one have to consider factors such as mechanical residential properties, corrosion resistance, thermal conductivity, and price. Reviewing the intended application and environmental conditions is essential for excellent selection.

What Are the Usual Flaws in Metal Casting?

Common flaws in Metal Casting consist of porosity, contraction, sand incorporation, and misruns. These concerns frequently develop from inappropriate product selection, inadequate layout, or defects in the casting process, influencing the end product's quality and performance.

Just How Can I Boost My Steel Casting Skills?

To improve Metal Casting abilities, one ought to exercise constantly, research study casting strategies, examine previous jobs for problems, look for responses from skilled casters, and continuously try out different materials and techniques to improve efficiency and understanding.

What Is the Cost of Beginning a Steel Casting Service?

Starting a steel casting business commonly requires an initial investment of $5,000 to $50,000, relying on equipment, products, and center prices. Variables like area and range can substantially affect total startup expenditures.

The Metal Casting procedure is a fundamental strategy in manufacturing that transforms molten metal right into strong forms. Beginners must comprehend the numerous methods entailed, such as sand casting and die spreading. There are several casting techniques, consisting of sand spreading, investment spreading, and die spreading, each with one-of-a-kind advantages and applications. Financial investment casting, or lost-wax casting, allows for complex layouts by utilizing a wax pattern that is melted away. Other approaches include irreversible mold and mildew spreading, which utilizes multiple-use mold and mildews, and centrifugal spreading, where rotational pressures assist in filling the mold and mildew.